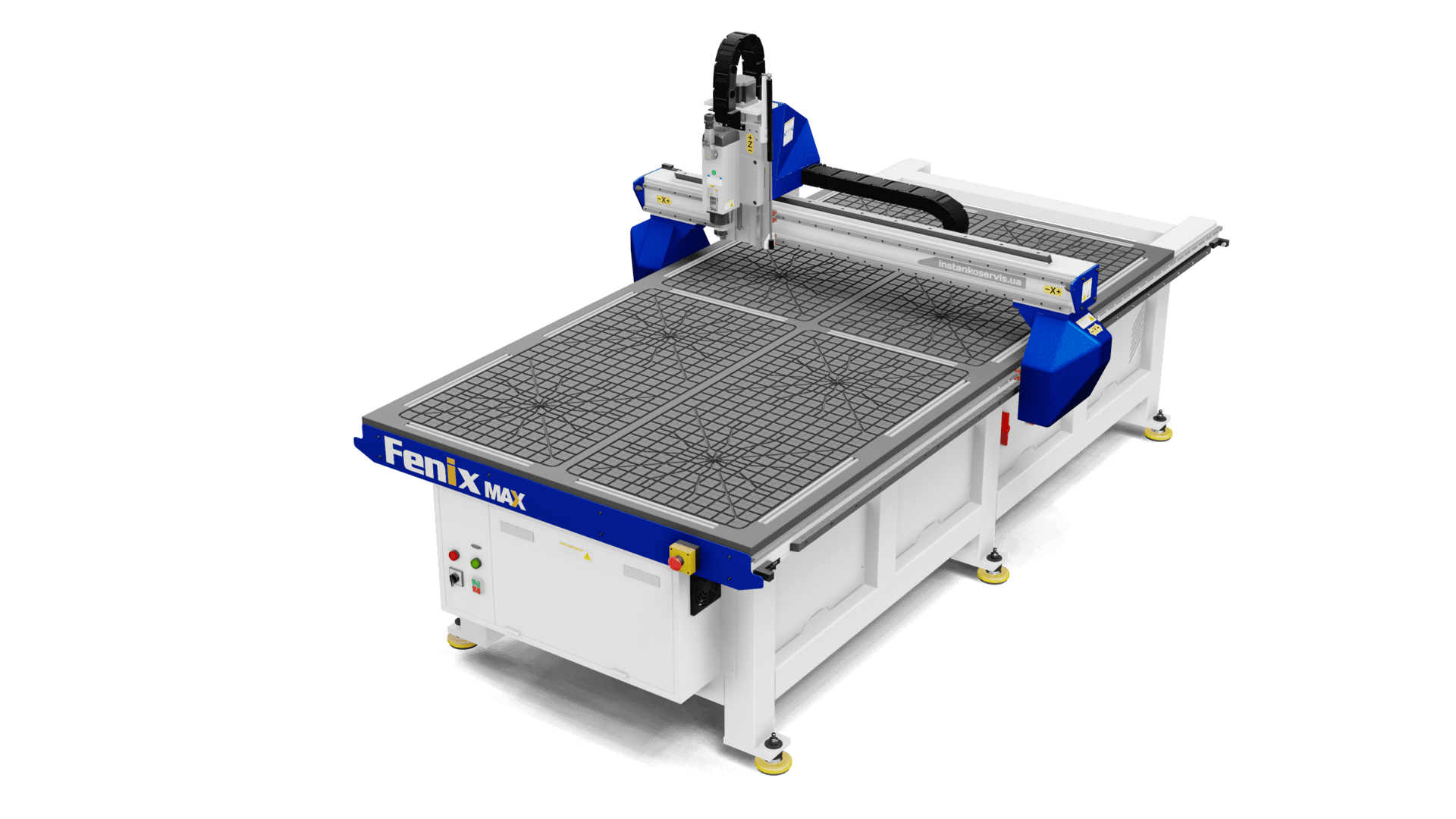

CNC router "Fenix.Max"

The CNC router “Fenix.Max” is a modification of one of the most popular Fenix CNC routers. The model of this machine has an enlarged worktable, which expands the possibilities of performing a wide range of tasks, including profile milling, engraving, cutting, and drilling of various materials.

The machine combines high productivity, reliability and low cost, which perfectly meets the needs of furniture and carpentry businesses.

The machine is easy to use, manage and affordable in its class. The CNC milling machine “Fenix.Max” is the best choice for business seeking to improve production efficiency without significant investments.

-

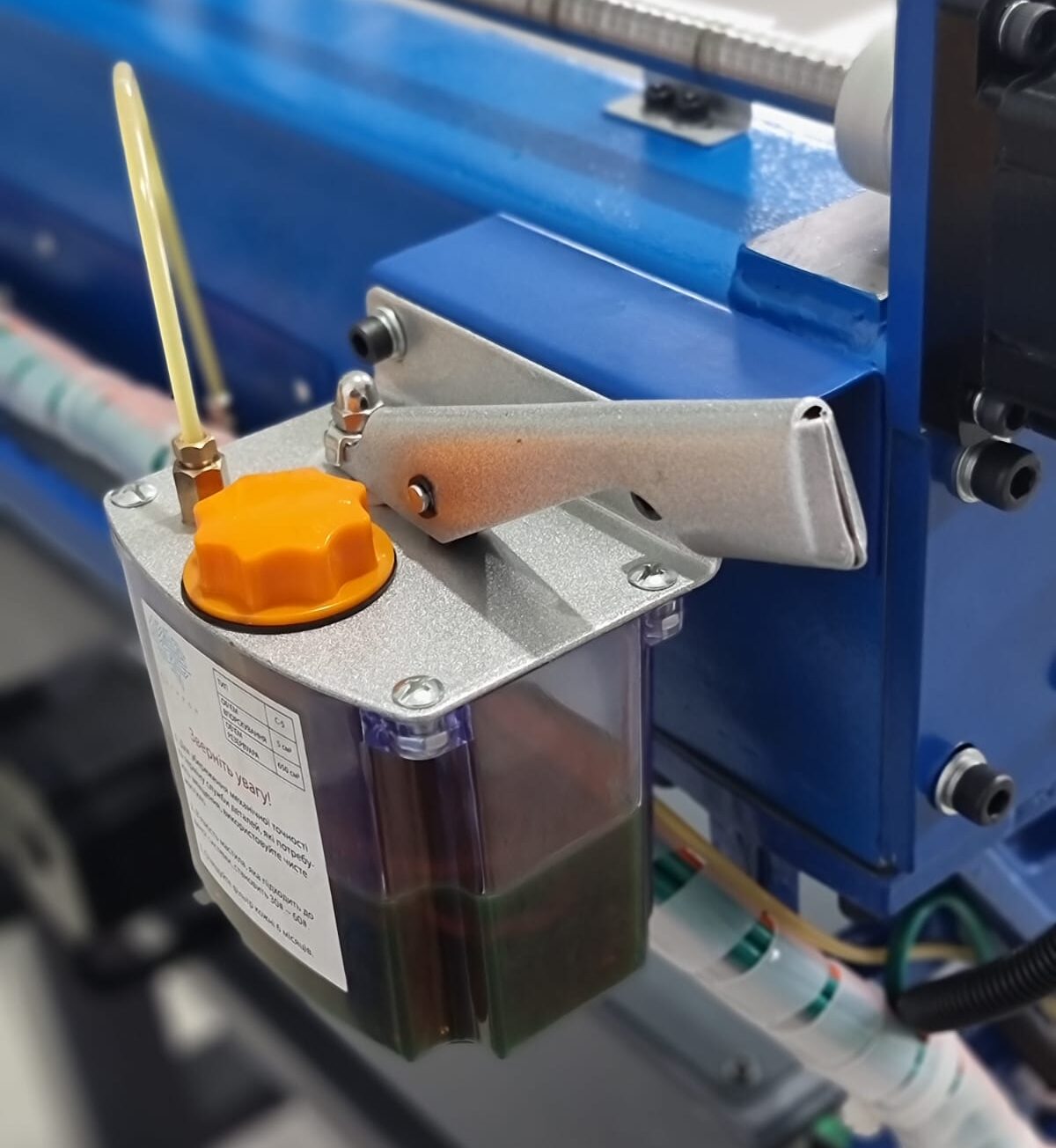

Quality components

During the production of CNC machines, we use only high-quality brand components. They guarantee the accuracy, reliability and long-term operation of CNC routers

-

Professional production

During the existence of the company, we have established ourselves as a professional production that is actively developing and working on the modernization of equipment and the creation of new models of machines

-

Reliable spindle

Our machines use high-quality spindles from the world’s leading manufacturers with liquid and air cooling. They ensure the accuracy of material processing

-

Simple controls

CNC machines are easy to use and have an intuitive interface and control system that allows you to quickly and efficiently meet your production goals

-

Software

We use exclusively professional and licensed software that guarantees efficient machine control and minimizes the risk of malfunctions

-

Service

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Guarantee

The guarantee for all CNC machines is one year. We also provide post-warranty technical support and equipment maintenance throughout our machines’ period of operation

-

Industrial manufacturing

Manufacturing of CNC machine tools takes place at our production base using precise equipment and careful observance of all the processes and standards of machine tool construction

Information

Information

The Fenix.Max model machine differs from the Fenix model by having an enlarged working area while maintaining the same level of quality, making it an equally reliable assistant in production.

Advantages of the model

- Affordable price

- Compact size of the machine

- Low energy consumption

- Professional construction of the machine

- User-friendly control system

Worktable size

Y-2500, X-1300, Z-200

Materials that can be processed

- Wood (timber, plywood, MDF, particle board, birch, walnut, etc.)

- Plastics (acrylic, Plexiglas, polycarbonate)

- Polystyrene and PVC

- Composite materials (Dibond and Alucobond)

- Soft metals (aluminum, brass, copper)

Application areas

- Furniture production

- Production of 3D decorations

- Outdoor advertising production

- Model building

- Jewelry production

- Making press molds

Construction

The machine’s solid welded frame is made of steel profile tubes. The portal supports are made of cast iron to avoid excessive vibrations during processing. To ensure the quality of the machine parts, they are processed on modern CNC metalworking equipment.

Specifications

Table work area (Y×X)

2500×1300 mm

Axes travel (Y×X×Z)

2500×1300×200 mm

Machine dimensions (L×W×H)

2850×1700×1600 mm

Machine weight

700 кg

Machine type

CNC router

Construction

Moving gantry

Spindle nut to table clearance

200 mm

Gantry clearance

150 mm

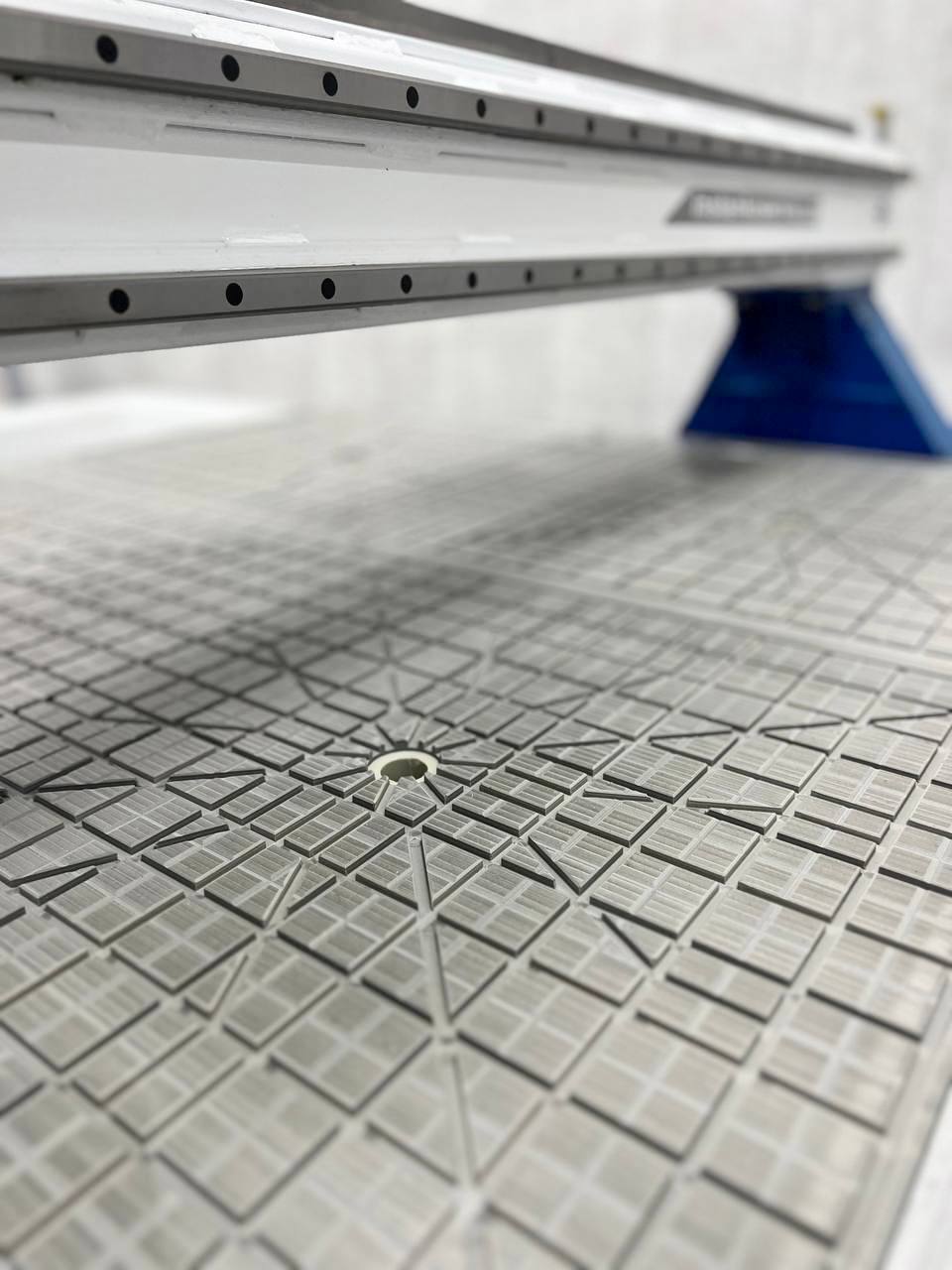

Worktable with mechanical workpiece fixturing

Profiled aluminum (T-slot)

Linear guide rails

Precision linear guideway

Z axis feed:

Ball screw drive

X, Y axes feed

Helical rack

Reducer type of X, Y axes

Toothed belt

X, Y, Z axes motors

Stepper motor

Maximum traverse speed, axis Z

6 m/min

Maximum traverse speed, axes X,Y

14 m/min

Work feed rate up to

до 14 m/min

Spindle power

3.5 кW

Spindle speed

6 000-18 000 rpm

Spindle cooling type

Air

Tool change

Manual

Сollet type

ER25

Maximum Ø of shank

16 mm

Tool length measurement sensor type

Contact

Limit switches

Inductive

Control system (CNC)

DSP

Programming language

G-Code

Dust collection port Ø

100 mm

Recommended dust collection performance

3200 m3/hour

Power requirements

380/220 V, 50 Hz

Maximum power consumption

5 кW

FAQ

Do you conduct machine installation and training?

Yes, we do. Upon the client’s request, our specialists perform installation work and provide training on the basics of machine operation and creating toolpaths.

Can a 4th axis be added later on?

To effortlessly install a 4th axis (such as a rotary axis) later on, we recommend ordering the “preparation for the 4th axis” option along with the machine.

Which control system should I choose?

The ATS-0609 can be operated with two types of controllers: 1. DSP controler; 1. NC Studio CNC system. The advantages of the DSP controller its compact size, simplicity, and ease of use, as well as the fact that there is no need to purchase a PC. The disadvantages of DSP controller include limited screen informativeness and fragility (it may malfunction if dropped). The NC Studio CNC system, when used with a PC, significantly reduces programming time and minimizes the risk of errors. However, it does require a computer system unit with a 32-bit Windows operating system.

How do you create toolpaths for the machine?

Various CAM software allows the creation of toolpaths, such as V-Carve, ArtCAM, Rhinoceros, Deskproto, etc. We recommend considering using toolpath generation features within CAM software. We also offer a comprehensive training course on how to utilize these toolpath features effectively.

Can the working area of the machine be increased?

It’s possible to consider increasing the machine’s working area upon the client’s request. However, we recommend paying attention to the “ATS” series, which includes large-format milling machines designed specifically for this purpose.

Is this model available in 380 volts?

Two types of power supply are used in this range of machines: 220 volts and 380 volts. By default, the machine is equipped with 220-volt equipment, but it can be changed for 380 volts upon the customer’s request.

Do you offer shipping?

Depending on the region of Ukraine, we provide equipment shipping through our transportation or other courier companies. We have also developed turnkey solutions for overseas businesses.

Is there post-warranty support and maintenance available?

We provide post-warranty support and service for all our machines. Mechanical and electrical parts used in our machines are always in stock.

Дізнатись вартість

Дізнатись вартість та наявність фрезерного верстата з ЧПУ «Fenix.Max» можна на сайті нашого магазину

Якщо вас зацікавила ця модель верстата, будемо раді отримати ваші виробничі завдання та надати професійну консультацію!

Будь ласка, звертайтесь!