CNC laser machine "LSK-3015"

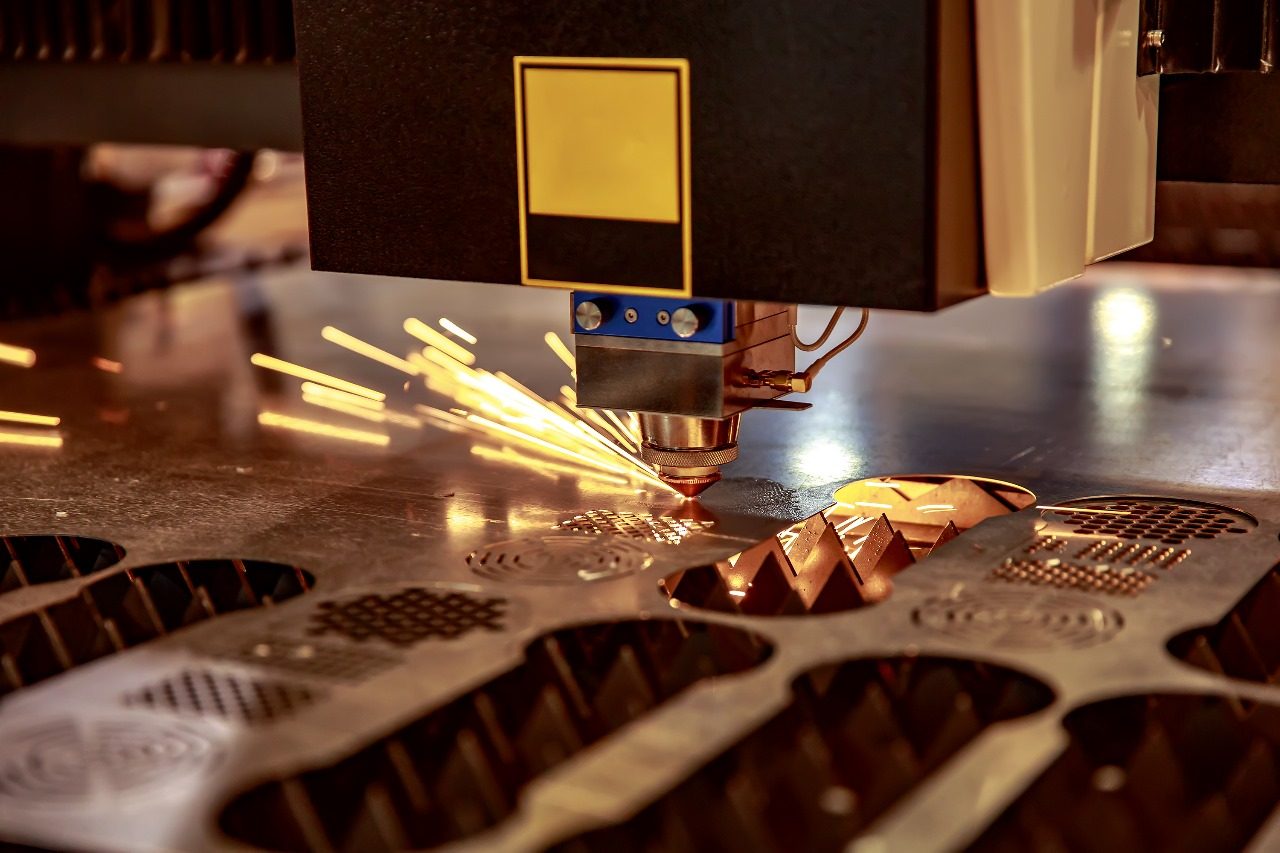

Multifunctional high-precision equipment that is successfully used in almost all production areas. The CNC laser machine “LSK-3015” has several advantages, including the minimum width of cut and low waste amount, as well as the high edge quality without additional processing.

The machine has an ventilation unit to remove gases from the working area. To ensure a long service life, all machine mechanical components are protected by bellow protections.

A CNC fibre laser machine allows effectively cope with tasks requiring high accuracy and cutting quality.

-

Quality components

During the production of CNC machines, we use only high-quality brand components. They guarantee the accuracy, reliability and long-term operation of CNC routers

-

Professional production

During the existence of the company, we have established ourselves as a professional production that is actively developing and working on the modernization of equipment and the creation of new models of machines

-

Reliable spindle

Our machines use high-quality spindles from the world’s leading manufacturers with liquid and air cooling. They ensure the accuracy of material processing

-

Simple controls

CNC machines are easy to use and have an intuitive interface and control system that allows you to quickly and efficiently meet your production goals

-

Software

We use exclusively professional and licensed software that guarantees efficient machine control and minimizes the risk of malfunctions

-

Service

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Guarantee

The guarantee for all CNC machines is one year. We also provide post-warranty technical support and equipment maintenance throughout our machines’ period of operation

-

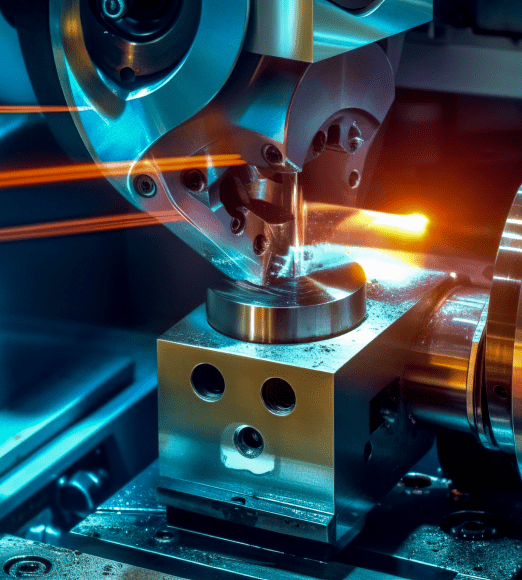

Industrial manufacturing

Manufacturing of CNC machine tools takes place at our production base using precise equipment and careful observance of all the processes and standards of machine tool construction

Information

Information

The LSK-3015 machine represents modern technology that ensures high quality and precision in cutting sheet metal. To achieve this performance, a ytterbium fiber laser source is utilized.

Advantages of the model

- Affordable price;

- Fast and reliable operation;

- Sturdy construction;

- User-friendly control system

Worktable size

Y-3000, X-1500

Materials that can be processed

- Carbon steels

- Alloy steels

- Non-ferrous metals

Application areas

- Construction industry

- Mechanical Engineering

- Aerospace industry

- Shipbuilding

- Advertising production

Construction

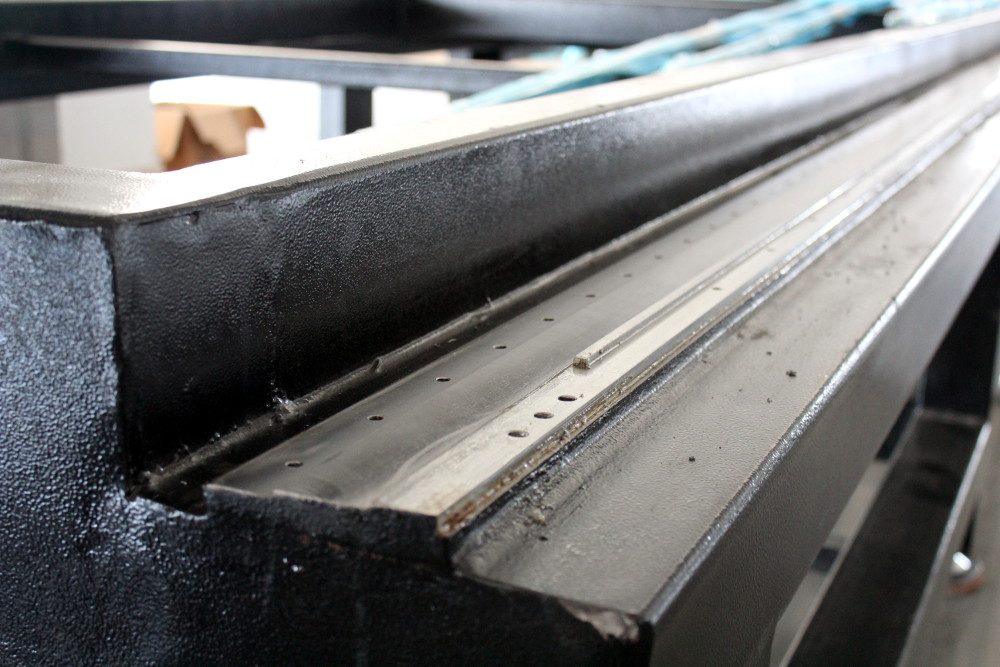

The machine’s solid welded frame is made of steel profile tubes. The portal supports are made of cast iron to avoid excessive vibrations during processing. To ensure the quality of the machine parts, they are processed on modern CNC metalworking equipment.

A modern industrial CNC controller operates the machine.

Specifications

Machine type

Fiber Laser

Construction

Moving gantry

Table work area (Y×X)

1500×3000 mm

Axes travel (Y×X×Z)

1500×3000×100 mm

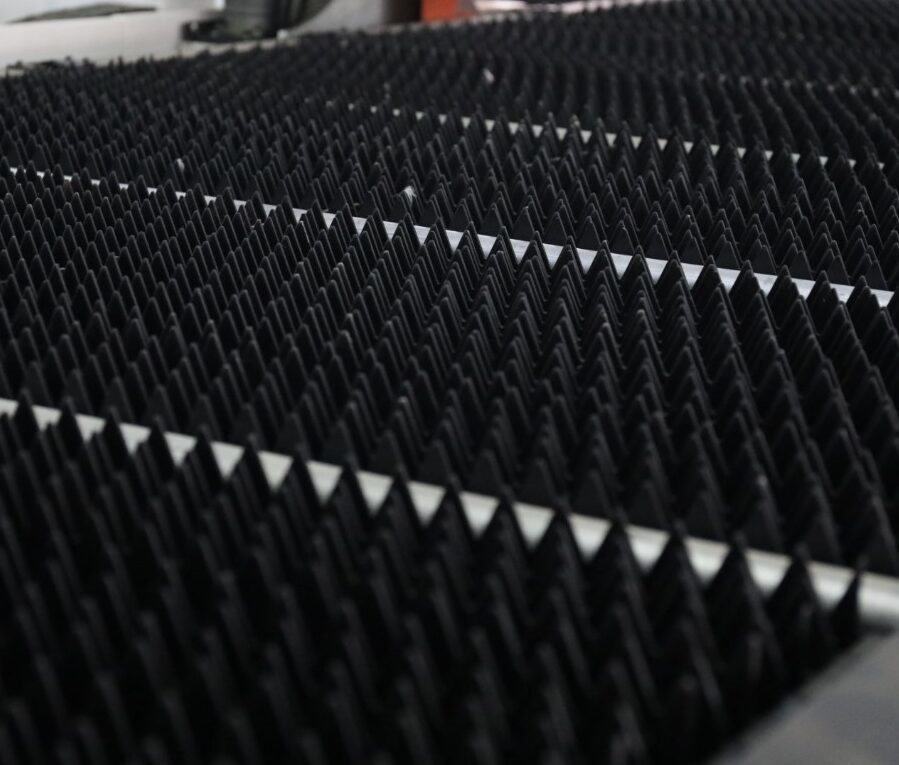

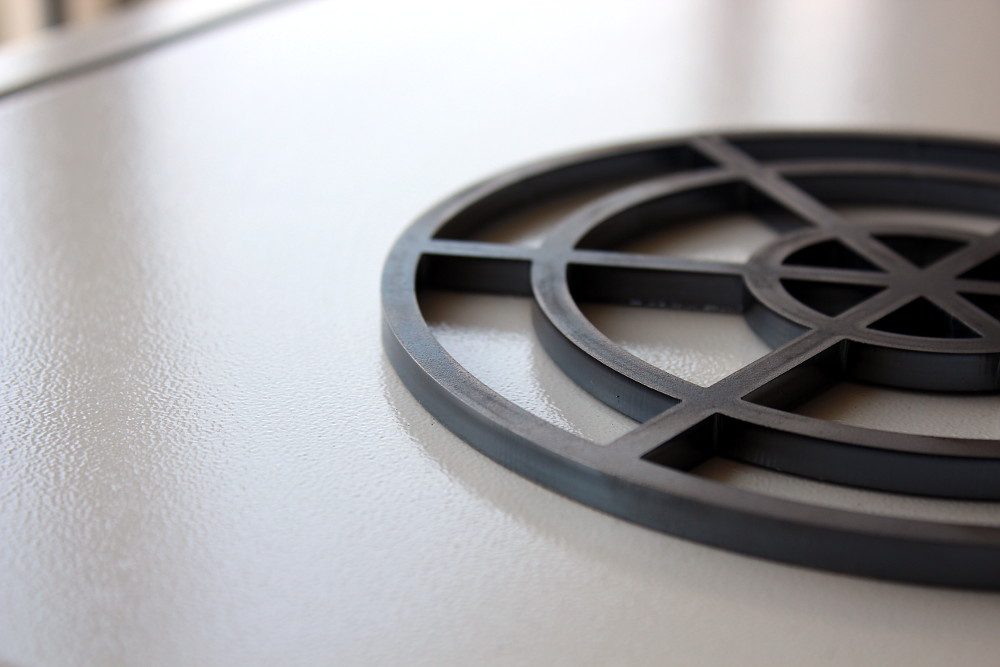

Worktable:

Slatted

Linear guide rails:

Precision linear guideway

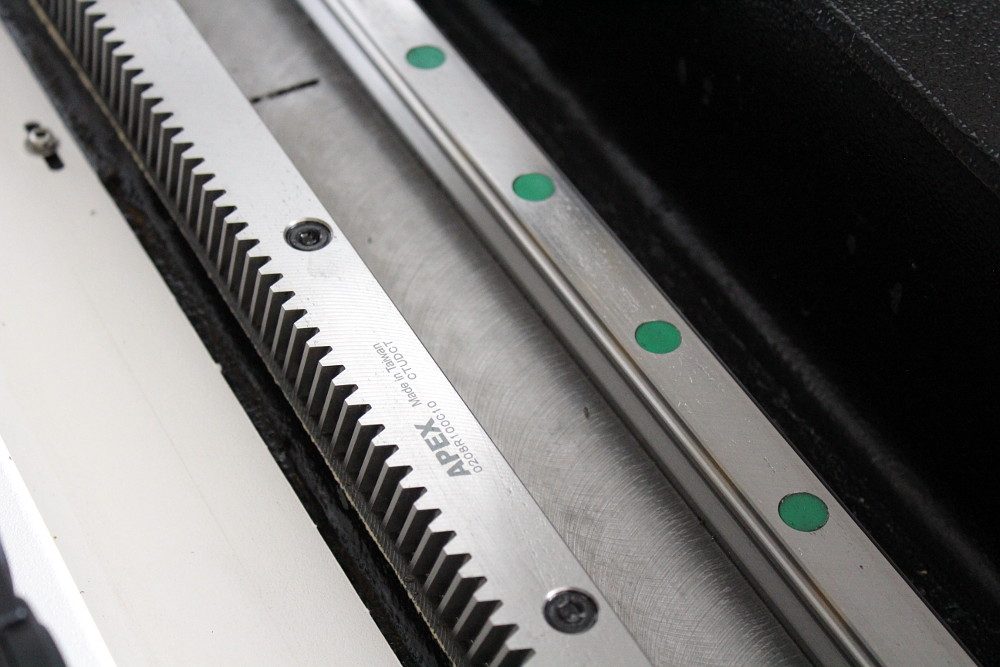

X, Y axes feed:

Косозуба рейка

Z axis feed:

Ball screw drive

X, Y axes motors:

Servo drive with planetary reducer

Maximum traverse speed, axes X, Y

40 m/min

Work feed rate up to

1-40 m/min

Laser tube manufacturer

Raicus

Laser wavelength

1080 Nm

Laser power

500 – 3000 W

Laser cooling:

Chiller

Laser power adjustment:

Software

Control system

SC1000

Software

SC1000

Exhaust port Ø

150 mm

Exhaust fan

1500 m3/hour

Auxiliary gas

N2 | O2

Power requirements

220 V, 50 Hz

Power consumption

7 – 28 кW

Machine dimensions (L×W×H)

4460×2450×2000 mm

Machine weight

2500 кg

FAQ

Do you conduct machine installation and training?

Yes, we do. Upon the client’s request, our specialists perform installation work and provide training on the basics of machine operation and creating toolpaths.

Can an exchange table be added?

An exchange table is an additional option for the LS-3015 fibre laser machine. The machine’s design allows for its use with and without a exchange table.

What capabilities does a 3 kW laser source offer?

The technical capabilities of a 3 kW laser source allow for cutting the following materials: carbon steel up to 20 mm thick, stainless steel up to 10 mm, aluminium up to 10 mm, copper up to 6 mm, and brass up to 5 mm.

What types of gases are used?

In the operation of a laser, two types of auxiliary gases are commonly used:

- Oxygen

- Nitrogen

Oxygen cutting is employed for carbon steels and steels with low alloying element content.

Nitrogen is used for cutting stainless steel, high-alloy steel, aluminium, and nickel.

Can colour metals and stainless steel be cut?

Fibre laser cutting machines allow the cutting of colour metals and stainless steel. Nitrogen is used as the auxiliary gas for such operations.

What is the cutting speed of a CNC machine?

Get New Quote Today

The machine can be produced in various modifications and equipped with options of your choice.

We can help you choose the optimal machine for your projects. Get Pricing Info & Have Our Machine Quick Reference Guide E-Mailed To You Today!