VPL-27.A vacuum press

The equipment is used for complete and quick cladding of surfaces with PVC film or veneer.

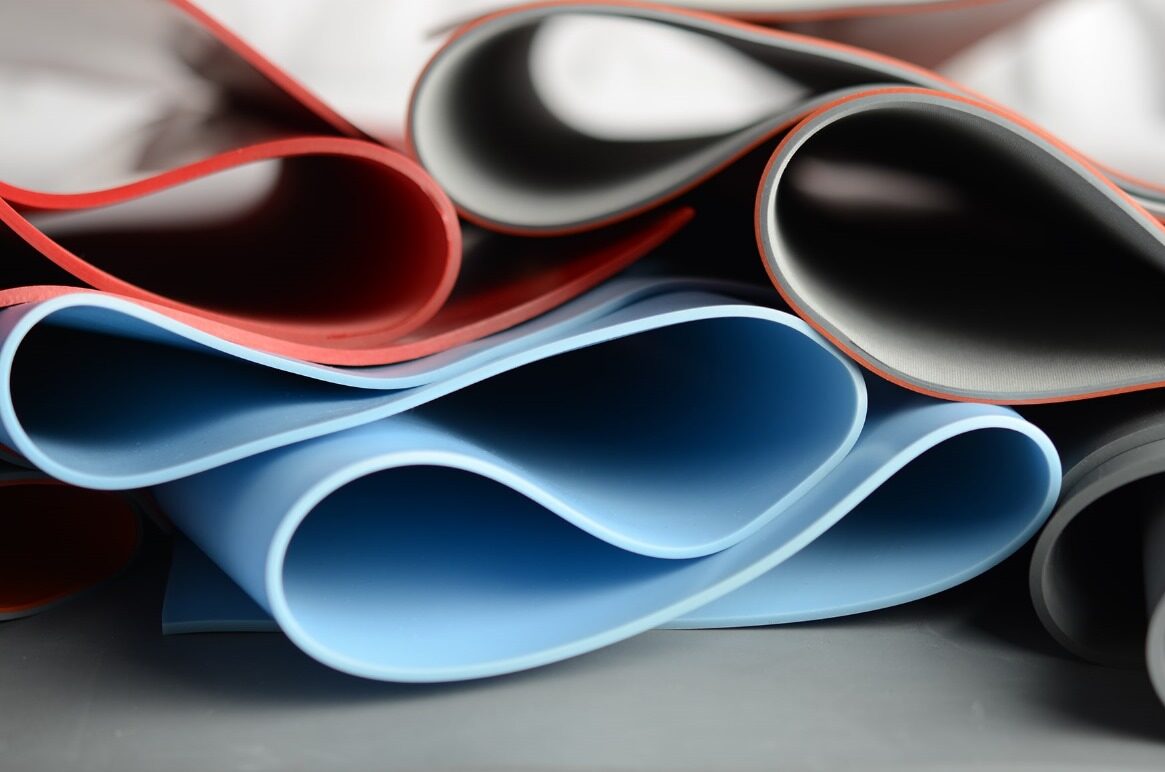

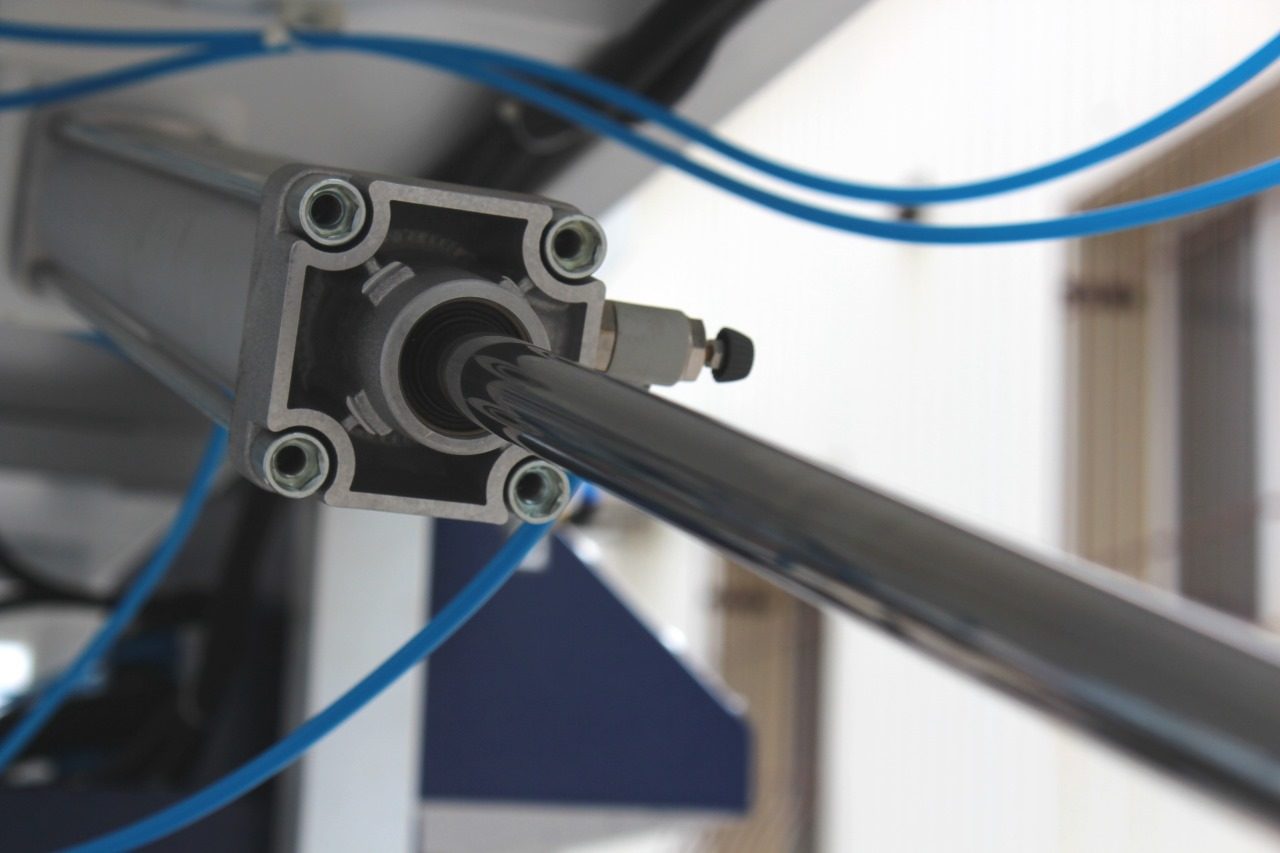

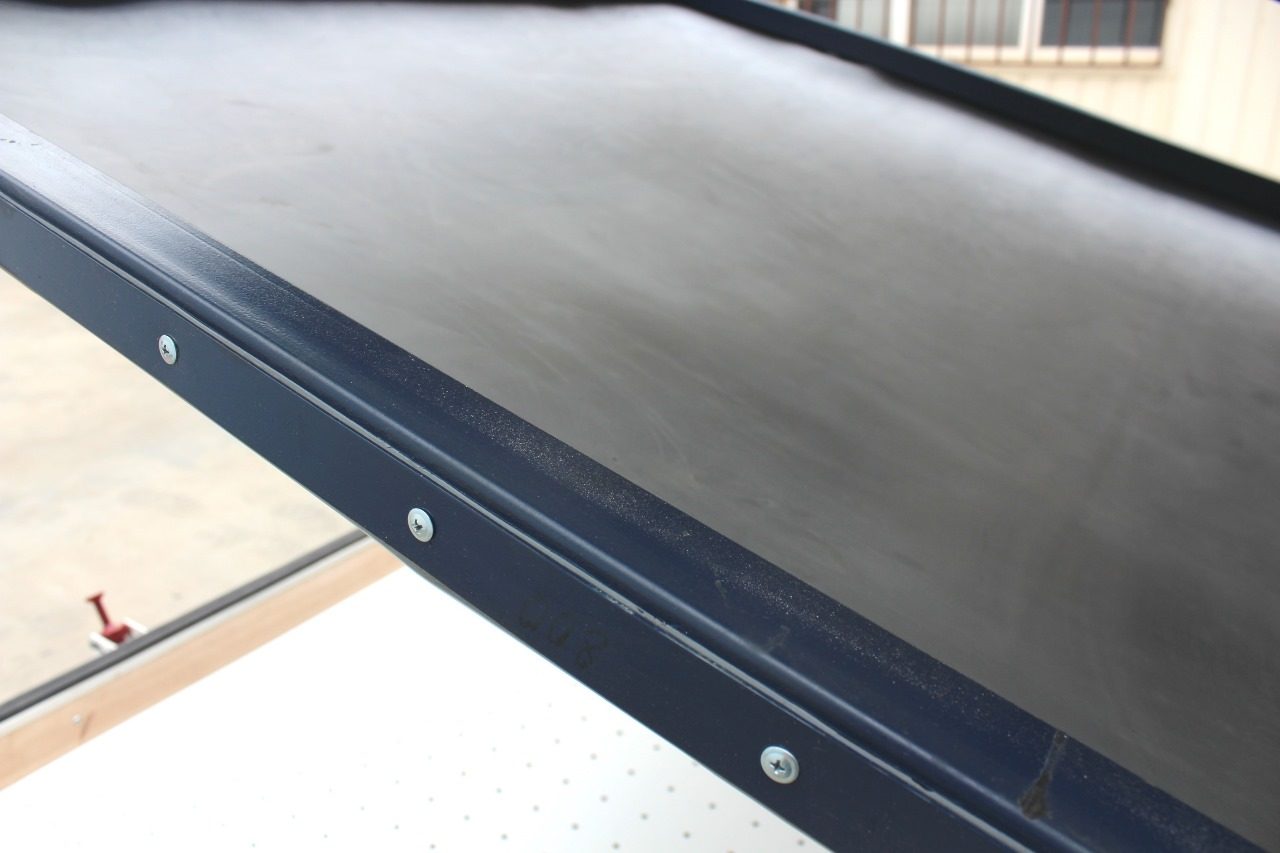

The vacuum table is the base for the processed material for further pressing operations. The vacuum pump draws air from the film covering, which is attached to the furniture workpieces. The clamping frame provides the tightness of the working area. The press cover can be made as a folding or rolling mechanism.

The vacuum press can also be equipped with a silicone membrane attached to the clamping frame using hook connections. This membrane performs the function of an additional press due to the reliable fixation of the parts.

-

Quality components

During the production of CNC machines, we use only high-quality brand components. They guarantee the accuracy, reliability and long-term operation of CNC routers

-

Professional production

During the existence of the company, we have established ourselves as a professional production that is actively developing and working on the modernization of equipment and the creation of new models of machines

-

Reliable spindle

Our machines use high-quality spindles from the world’s leading manufacturers with liquid and air cooling. They ensure the accuracy of material processing

-

Simple controls

CNC machines are easy to use and have an intuitive interface and control system that allows you to quickly and efficiently meet your production goals

-

Software

We use exclusively professional and licensed software that guarantees efficient machine control and minimizes the risk of malfunctions

-

Service

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Guarantee

The guarantee for all CNC machines is one year. We also provide post-warranty technical support and equipment maintenance throughout our machines’ period of operation

-

Industrial manufacturing

Manufacturing of CNC machine tools takes place at our production base using precise equipment and careful observance of all the processes and standards of machine tool construction

Information

Information

The vacuum pressing technology is based on laminating the surface with veneer or PVC film by placing the sample in a heat-resistant chamber with a previously applied adhesive compound. The chamber is heated to the required temperature, and air is extracted with the help of a vacuum pump to create a negative internal pressure, allowing the applied material to adhere firmly.

Advantages of the model

- Semi-automatic heater lift

- Pneumatic chamber locks

- Chamber heating speed

- Convenient membrane installation

- Temperature control sensor

Worktable size

2200x1100x200 mm

Materials that can be processed

- PVC film

- Veneer

- Plastic

Application areas

- Production of kitchen facades

- Production of furniture panels

- Production of door overlays

- Production of furniture structures

Construction

The vacuum press construction is based on profiled metal tubes. Infrared lamps are installed in the upper cover of the chamber to serve as the heating source. A special construction made of MDF sheets retains heat in the working area of the table. Pneumatic systems enable convenient control of the press operation.

Specifications

Construction

Hinged heater

Width of the work table

1280 mm

Length of the work table

2380 mm

Table material

MDF

Overall size of the clamping frame (L×W)

2500х1400 mm

Usable area of the work table

2,42 m2

Maximum height of the workpiece

200 mm

Height of the heating module

300 mm

Power requirements

380 В, 50 Hz

Power consumption of the vacuum system

1,1 кW

Power consumption of the heating elements

24 кW

Vacuum pump productivity

40 m3/hour

Vacuum pump brand

Zinisan

Maximum heating temperature

180 °C

Smooth adjustment of heating power

Yes

Heating temperature control

Automatic / Manual

Transport dimensions (L×W×H)

2380х1830х1400 mm

Weight

550 кg

Поширені запитання

Do you conduct machine installation and training?

Yes, we do. Upon the client’s request, our specialists perform installation work and provide training on the basics of machine operation and creating toolpaths.

Can the working area of the press be increased?

The working area of the press, in its standard configuration, is 2200×1100 mm. This working area can be increased or decreased according to the customer’s technical requirements.

How do I veneer products?

From which side does the lid open?

Is there post-warranty support and maintenance available?

We provide post-warranty support and service for all our machines. Mechanical and electrical parts used in our machines are always in stock.

How do you protect a CNC machine from power surges?

As the manufacturer, we also recommend installing a voltage stabilizer at the CNC machine’s input to ensure stable operation and avoid issues related to power surges.

Do you offer shipping?

Depending on the region of Ukraine, we provide equipment shipping through our transportation or other courier companies. We have also developed turnkey solutions for overseas businesses.

Get New Quote Today

The machine can be produced in various modifications and equipped with options of your choice.

We can help you choose the optimal machine for your projects. Get Pricing Info & Have Our Machine Quick Reference Guide E-Mailed To You Today!