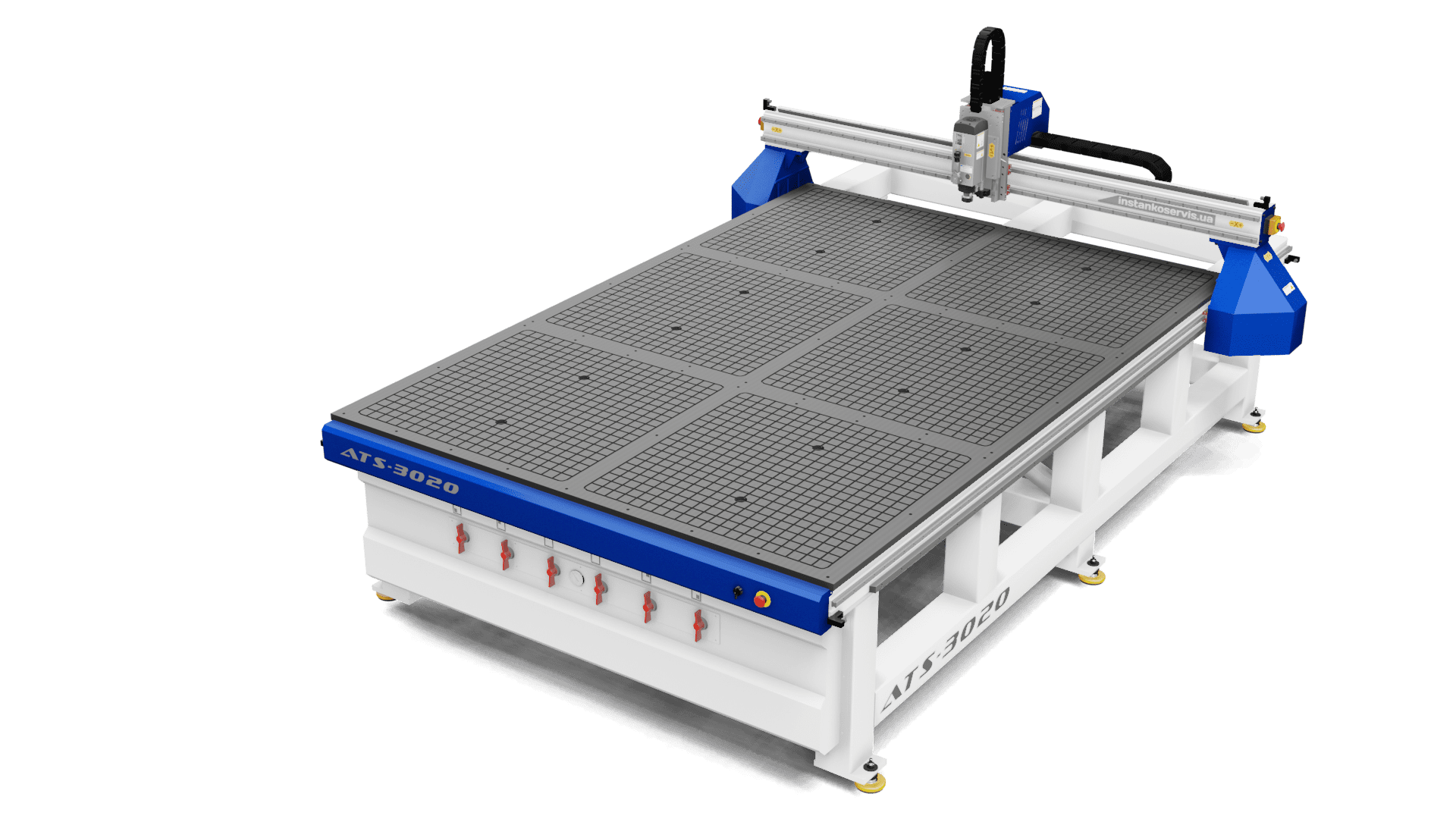

CNC machine «ATS-3020»

The full-size CNC machine, with a processing area of 3100 mm x 2100 mm, is designed for processing uncut sheets of MDF, chipboard, plywood, PVC, acrylic, etc.

This machine’s advantage is its large working field, which simplifies and speeds up the milling process. You can save time because sheets do not need to be preliminary cut on third-party equipment, such as a format-cutting machine. The sheet material cutting operation can be performed as part of the control program, thus automating the production cycle.

The ATS-3020 CNC machine is an excellent investment in cabinet furniture, outdoor advertising production businesses, and businesses that provide cutting materials services.

-

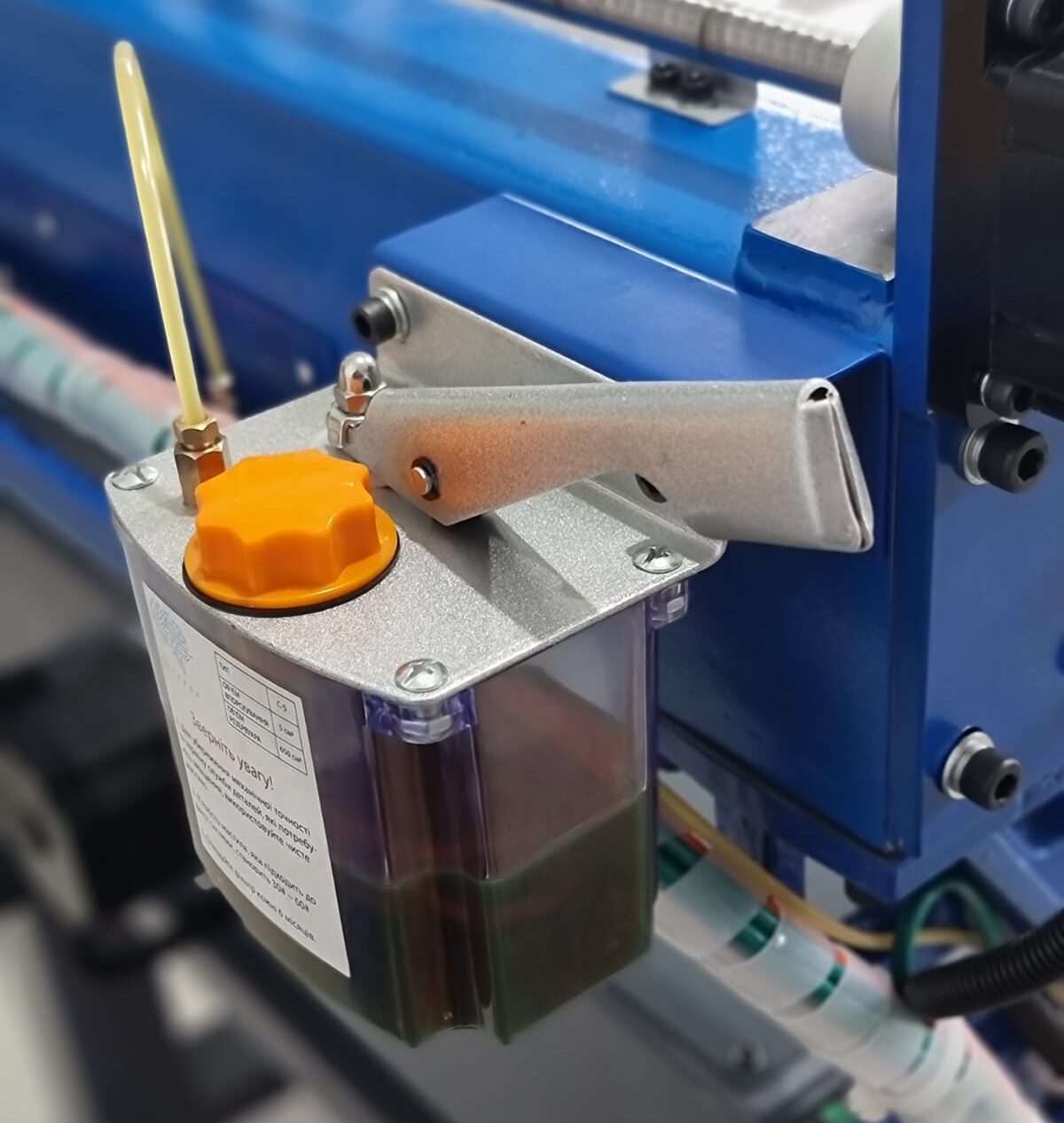

Quality components

During the production of CNC machines, we use only high-quality brand components. They guarantee the accuracy, reliability and long-term operation of CNC routers

-

Professional production

During the existence of the company, we have established ourselves as a professional production that is actively developing and working on the modernization of equipment and the creation of new models of machines

-

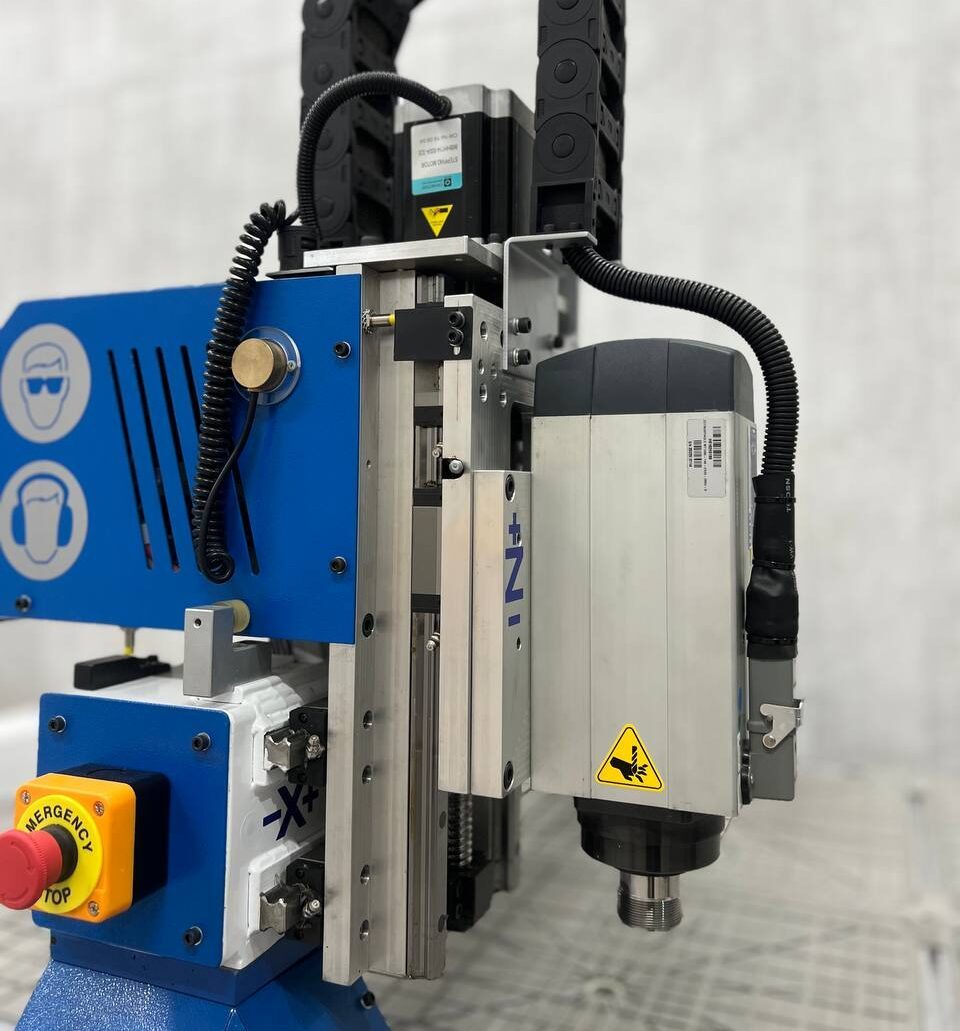

Reliable spindle

Our machines use high-quality spindles from the world’s leading manufacturers with liquid and air cooling. They ensure the accuracy of material processing

-

Simple controls

CNC machines are easy to use and have an intuitive interface and control system that allows you to quickly and efficiently meet your production goals

-

Software

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Service

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Guarantee

The guarantee for all CNC machines is one year. We also provide post-warranty technical support and equipment maintenance throughout our machines’ period of operation

-

Industrial manufacturing

Manufacturing of CNC machine tools takes place at our production base using precise equipment and careful observance of all the processes and standards of machine tool construction

Information

Information

The ATS-3020 model has a large working area and is most commonly used for processing large-sized sheet materials. This machine allows the use of the “Nesting” cutting technology.

Advantages of the model

- High productivity

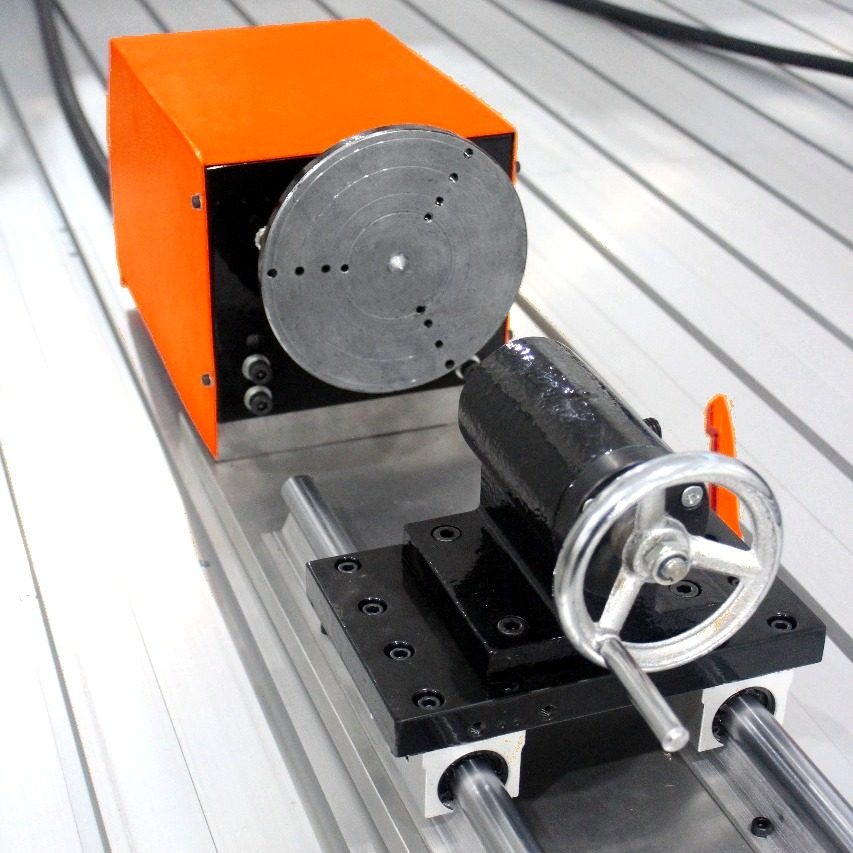

- Additional options

- Sturdy construction

- Fast and reliable operation

- User-friendly control system

Worktable size

Y-3100, X-2100, Z-200*

*Possible increase of Z-axis travel up to 300 mm

Materials that can be processed

- Wood (timber, plywood, MDF, particle board, birch, walnut, etc.)

- Plastics (acrylic, Plexiglas, polycarbonate)

- Composite materials (Dibond and Alucobond)

- Soft metals (aluminum, brass, copper)

Application areas

- Furniture production

- Production of 3D decorations

- Outdoor advertising production

- Model building

- Jewelry production

- Making press molds

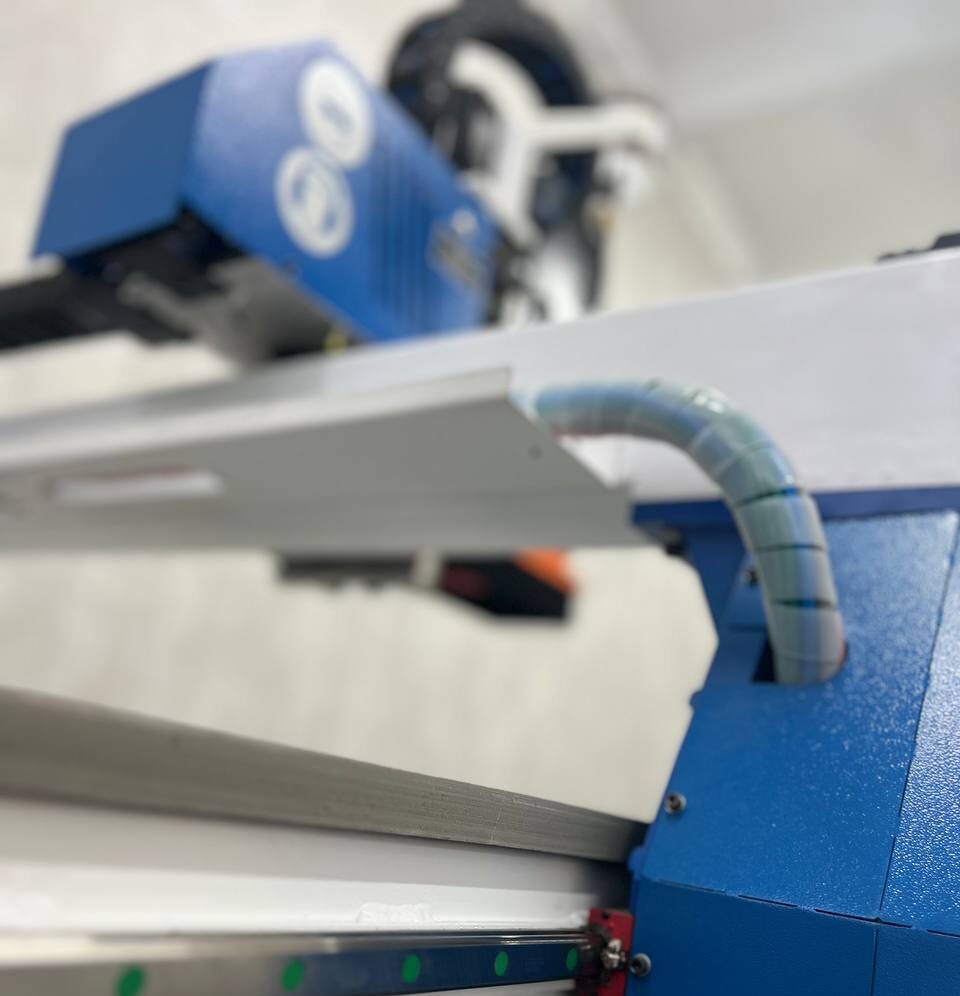

Construction

The machine’s solid welded frame is made of steel profile tubes. The portal supports are made of cast iron to avoid excessive vibrations during processing. To ensure the quality of the machine parts, they are processed on modern CNC metalworking equipment.

A modern industrial CNC controller operates the machine.

Specifications

Table work area (Y×X)

3100×2100 mm

Axes travel (Y×X×Z)

3100×2100×200 mm

Machine dimensions (L×W×H)

3800×2700×1700 mm

Machine weight

1100 кg

Machine type

CNC router

Construction

Moving gantry

Spindle nut to table clearance

200 mm

Gantry clearance

200 mm

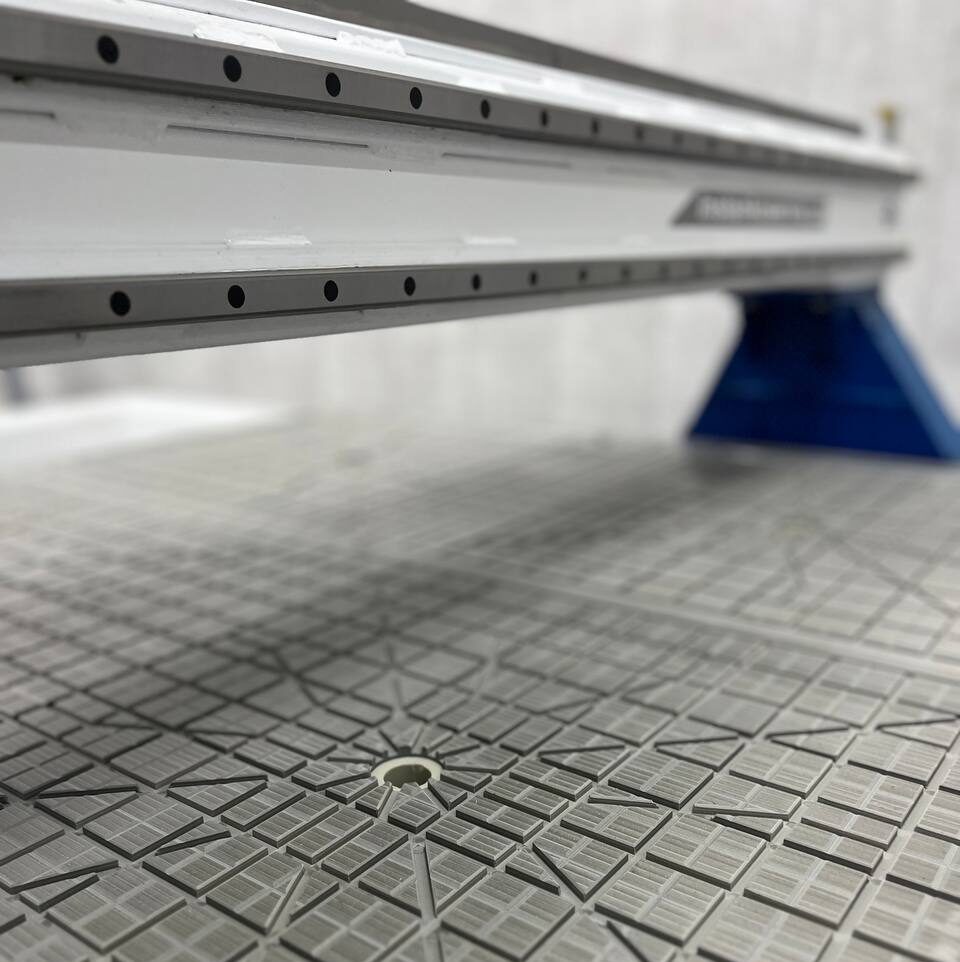

Worktable with mechanical workpiece fixturing

Profiled aluminum (T-slot)

Linear guide rails

Precision linear guideway

Z axis feed:

Ball screw drive

X, Y axes feed

Helical rack

Reducer type of X, Y axes

Toothed belt

X, Y, Z axes motors

Stepper motor

Maximum traverse speed, axis Z

6 m/min

Maximum traverse speed, axes X,Y

20 m/min

Work feed rate up to

15 m/min

Spindle power

3.5 кW

Spindle speed

6 000-18 000 rpm

Spindle cooling type

Air

Tool change

Manual

Collet type

ER25

Maximum Ø of shank

16 mm

Tool length measurement sensor type

Contact

Limit switches

Inductive

Control system (CNC)

NCStudio

Programming language

G-Code

Dust collection port Ø

100 mm

Recommended dust collection performance

3200 m3/hour

Power requirements

380 V, 50 Hz

Maximum power consumption

5 кW

FAQ

Do you conduct machine installation and training?

Yes, we do. Upon the client’s request, our specialists perform installation work and provide training on the basics of machine operation and creating toolpaths.

What CAM software should be used for "Nesting" technology?

Any software that supports saving the control program in G-code format can be used. For example: VCarve Pro, Aplhacam, NESTINGWorks, SigmaNest, VisualCAM, PowerShape/Mill, Fusion360 with Nesting AddOn, and others. For “Nesting” technology, our company uses VCarve Pro software from Vectric.

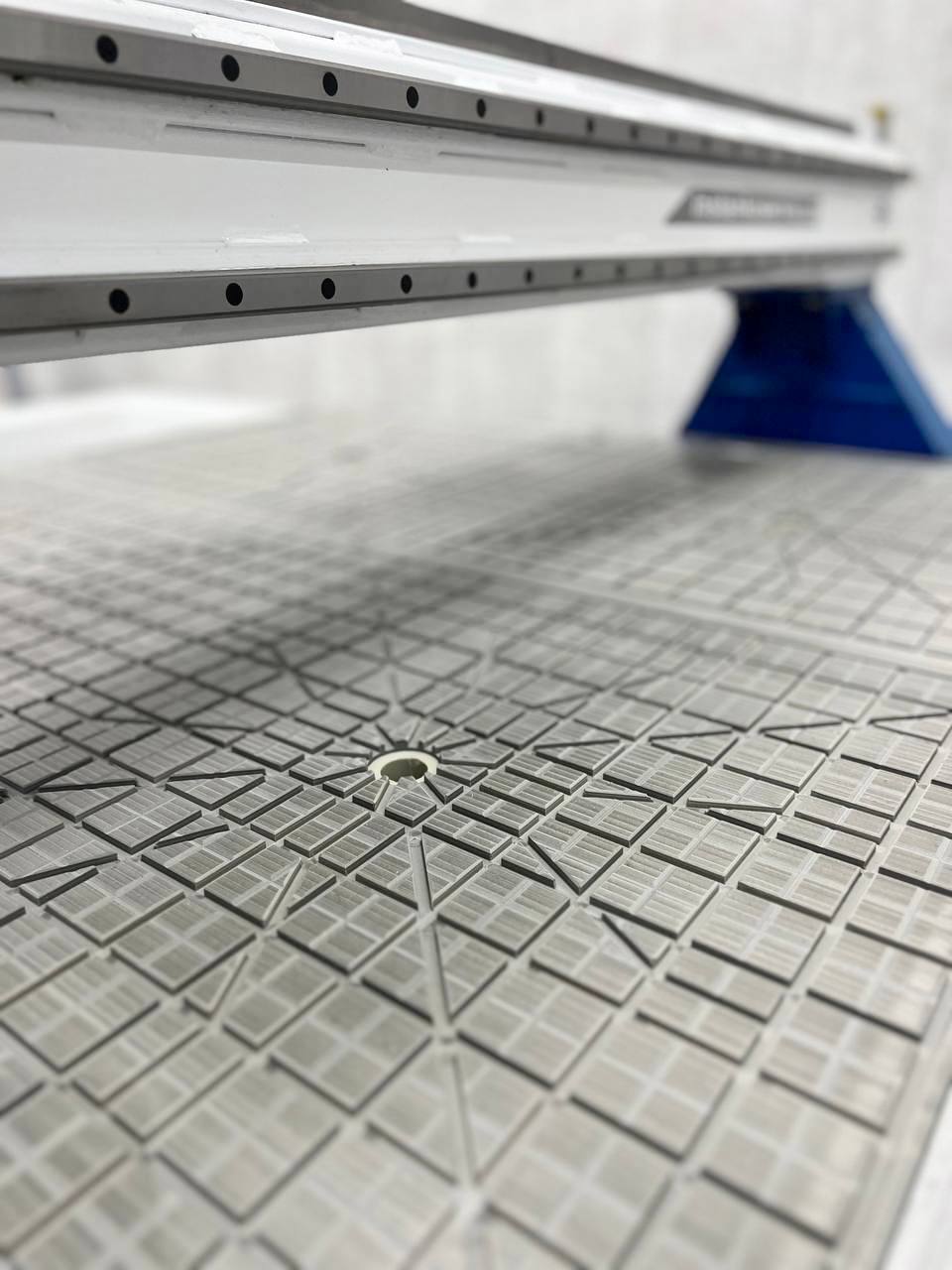

Is the vacuum pump sufficient to hold the workpiece?

The ATS-3020 machine’s vacuum table is equipped with a vacuum pump with a power of 5.5 kW, a maximum capacity of 320 m3/h, and a maximum discharge of 440 mbar. The pump’s high productivity, combined with a specially designed vacuum table construction, ensures quality and reliable workpiece clamping.

How can I control the vacuum table?

The vacuum table of a CNC machine is divided into several vacuum zones, which can be controlled in two ways:

- Mechanical valves on the machine’s front panel open/close the air supply to the vacuum zone;

- Electric valves are controlled by pressing the corresponding buttons.

How is the machine shipped?

The machine is shipped to you fully assembled, securely packed in its factory packaging. Due to its overall dimensions, it’s transported on appropriately sized transport vehicles, ensuring its safe and intact delivery to your location.

How do you protect a CNC machine from power surges?

As the manufacturer, we also recommend installing a voltage stabilizer at the CNC machine’s input to ensure stable operation and avoid issues related to power surges.

How do you create toolpaths for the machine?

Various CAM software allows the creation of toolpaths, such as V-Carve, ArtCAM, Rhinoceros, Deskproto, etc. We recommend considering using toolpath generation features within CAM software. We also offer a comprehensive training course on how to utilize these toolpath features effectively.

Is there post-warranty support and maintenance available?

We provide post-warranty support and service for all our machines. Mechanical and electrical parts used in our machines are always in stock.

Get New Quote Today

The machine can be produced in various modifications and equipped with options of your choice.

We can help you choose the optimal machine for your projects. Get Pricing Info & Have Our Machine Quick Reference Guide E-Mailed To You Today!