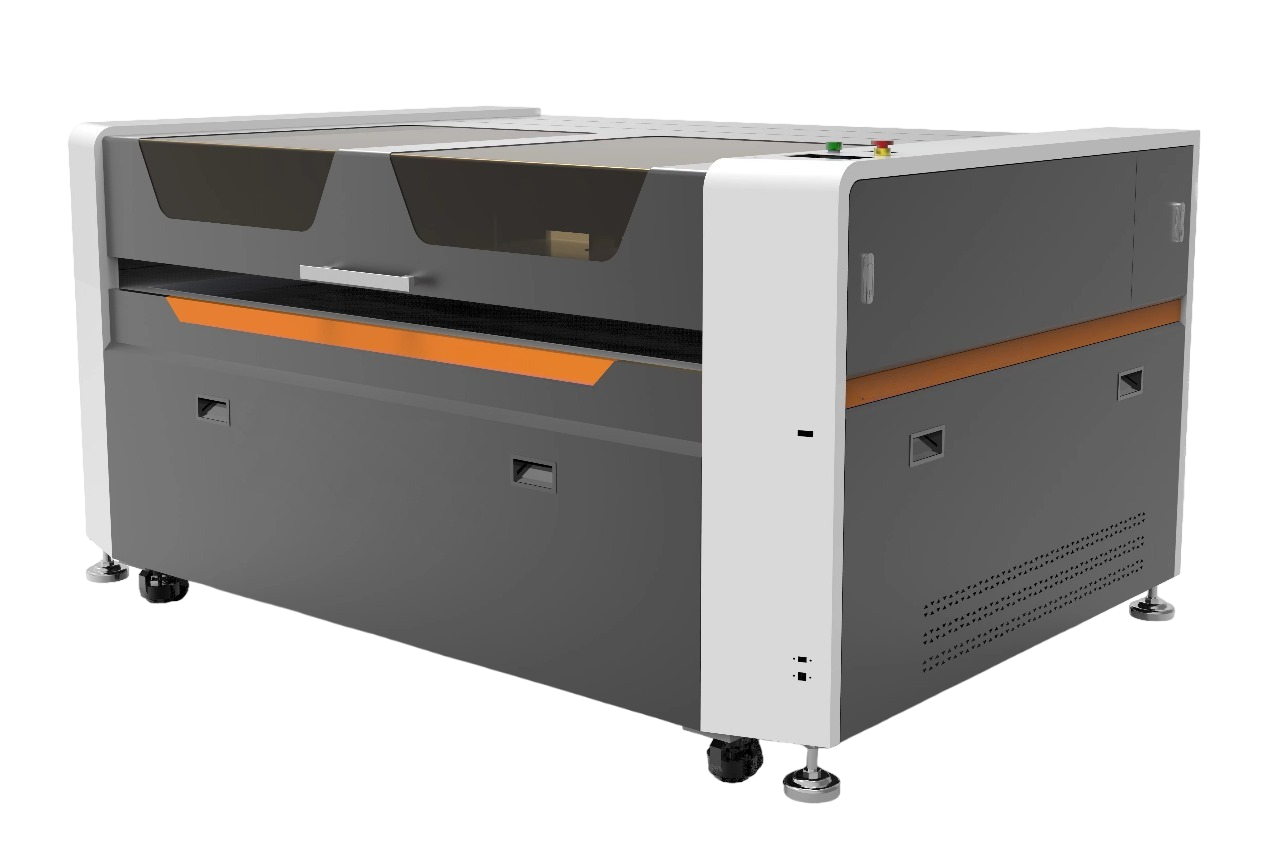

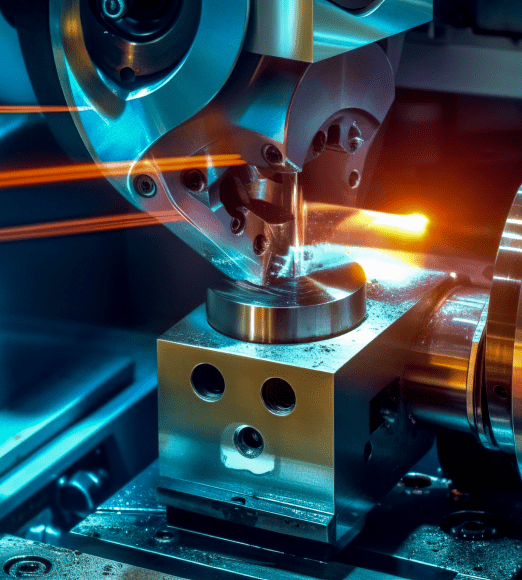

CNC Laser Cutting Machine "LS-1610"

The industrial-grade LS-1610 laser cutting machine is practical and user-friendly; it combines the reliability and durability of its components with reasonable price without compromising on quality.

The LS-1610 CNC laser cutting machine is widely utilized in the production of advertising, souvenir items and decorative elements in furniture manufacturing. It has proven itself as excellent auxiliary equipment for companies operating large-format machinery. And also it fits perfectly in small workshops and private homes.

-

Quality components

During the production of CNC machines, we use only high-quality brand components. They guarantee the accuracy, reliability and long-term operation of CNC routers

-

Professional production

During the existence of the company, we have established ourselves as a professional production that is actively developing and working on the modernization of equipment and the creation of new models of machines

-

Reliable spindle

Our machines use high-quality spindles from the world’s leading manufacturers with liquid and air cooling. They ensure the accuracy of material processing

-

Simple controls

CNC machines are easy to use and have an intuitive interface and control system that allows you to quickly and efficiently meet your production goals

-

Software

We use exclusively professional and licensed software that guarantees efficient machine control and minimizes the risk of malfunctions

-

Service

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Guarantee

The guarantee for all CNC machines is one year. We also provide post-warranty technical support and equipment maintenance throughout our machines’ period of operation

-

Industrial manufacturing

Manufacturing of CNC machine tools takes place at our production base using precise equipment and careful observance of all the processes and standards of machine tool construction

Information

Information

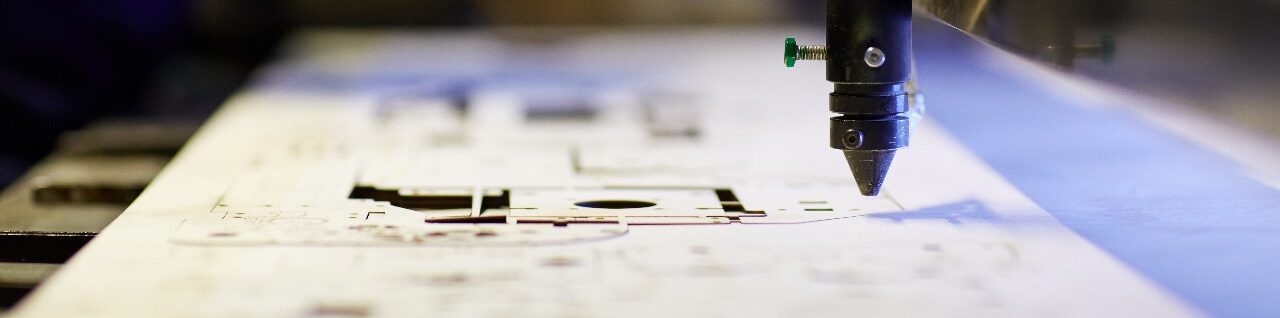

The “LS-1610” laser cutting machine is used for the production of advertising, souvenirs and decorative elements.

Advantages of the model

- Affordable price

- Fast and reliable operation

- Sturdy construction

- User-friendly control system

Worktable size

Y-1000, X-1600

Materials that can be processed

- Wood (timber, plywood, MDF, particle board, birch, walnut, etc.)

- Plastics (acrylic, Plexiglas, polycarbonate)

- Fabric (sewing, specialized)

- Gasket materials (rubber, paronite)

Application areas

- Making signs and plaques

- Souvenir production

- Textile industry

- Clothing and footwear production

- Toy manufacturing

Construction

The machine’s solid welded frame is made of steel profile tubes. The portal supports are made of cast iron to avoid excessive vibrations during processing. To ensure the quality of the machine parts, they are processed on modern CNC metalworking equipment.

A modern industrial CNC controller operates the machine.

Specifications

Machine type

Laser CO2

Table work area (Y×X)

X-1600 mm, Y-1000 mm

Moving table travel

250 mm

Laser power

100 W

Laser max power

130 W

Laser power adjustment

Software

Water chiller

CW5200

Chiller cooling capacity

1,4 кW

Axes drives

Stepper motors

X, Y axes feed

Зубчасті ремені HDT 3M

Linear guide rails

Профільовані (PMI, Тайвань)

Rapid travel speed

500 mm/sec

Worktable

Anodized aluminum slats + сотовий стіл

Control system (CNC)

Ruida

Software

RDWorks

Exhaust port Ø

150 mm

Exhaust fan

960 m3/hour

Air pump

5.7 m3/hour, 0.8 Bar

Power requirements

220 В, 50 Hz

Power consumption

до 2.0 кW

Weight

350 кg

Machine dimensions (L×W×H)

2510x1500x1100 mm

Warranty

12 month

FAQ

Do you conduct machine installation and training?

Yes, we do. Upon the client’s request, our specialists perform installation work and provide training on the basics of machine operation and creating toolpaths.

What is the lifespan of the laser tube?

The lifespan of a laser tube is not a one-size-fits-all figure. It depends on the manufacturer, cutting modes, cooling system, room temperature, and others. For instance, a well-known manufacturer like Reci provides an estimated lifespan of 15,000 hours for tubes up to 100 watts, 10,000 hours for 130 watts, and 8,000 hours for over 150 watts. This demonstrates the importance of choosing a reliable manufacturer when considering the lifespan of a laser tube. However, it’s crucial to remember that this lifespan is an estimate. The actual lifespan may vary depending on how the laser tube is used.

Is it possible to cut plywood?

The LS laser machines come with a base laser tube power of 100 watts. This power is sufficient for cutting plywood up to 10 millimetres thick. If there is a need to cut plywood thicker than 10 millimetres, a laser tube with a power of 130 watts or higher is required.

Can a more powerful laser tube be installed?

When materials with the greater thickness or specific characteristics need to be cut, or the load on the laser tube needs to be reduced, we can install laser tubes with the following power: 130 watts, 150 watts, and 180 watts.

Is there post-warranty support and maintenance available?

We provide post-warranty support and service for all our machines. Mechanical and electrical parts used in our machines are always in stock.

How is the machine shipped?

The machine is shipped to you fully assembled, securely packed in its factory packaging. Due to its overall dimensions, it’s transported on appropriately sized transport vehicles, ensuring its safe and intact delivery to your location.

Get New Quote Today

The machine can be produced in various modifications and equipped with options of your choice.

We can help you choose the optimal machine for your projects. Get Pricing Info & Have Our Machine Quick Reference Guide E-Mailed To You Today!