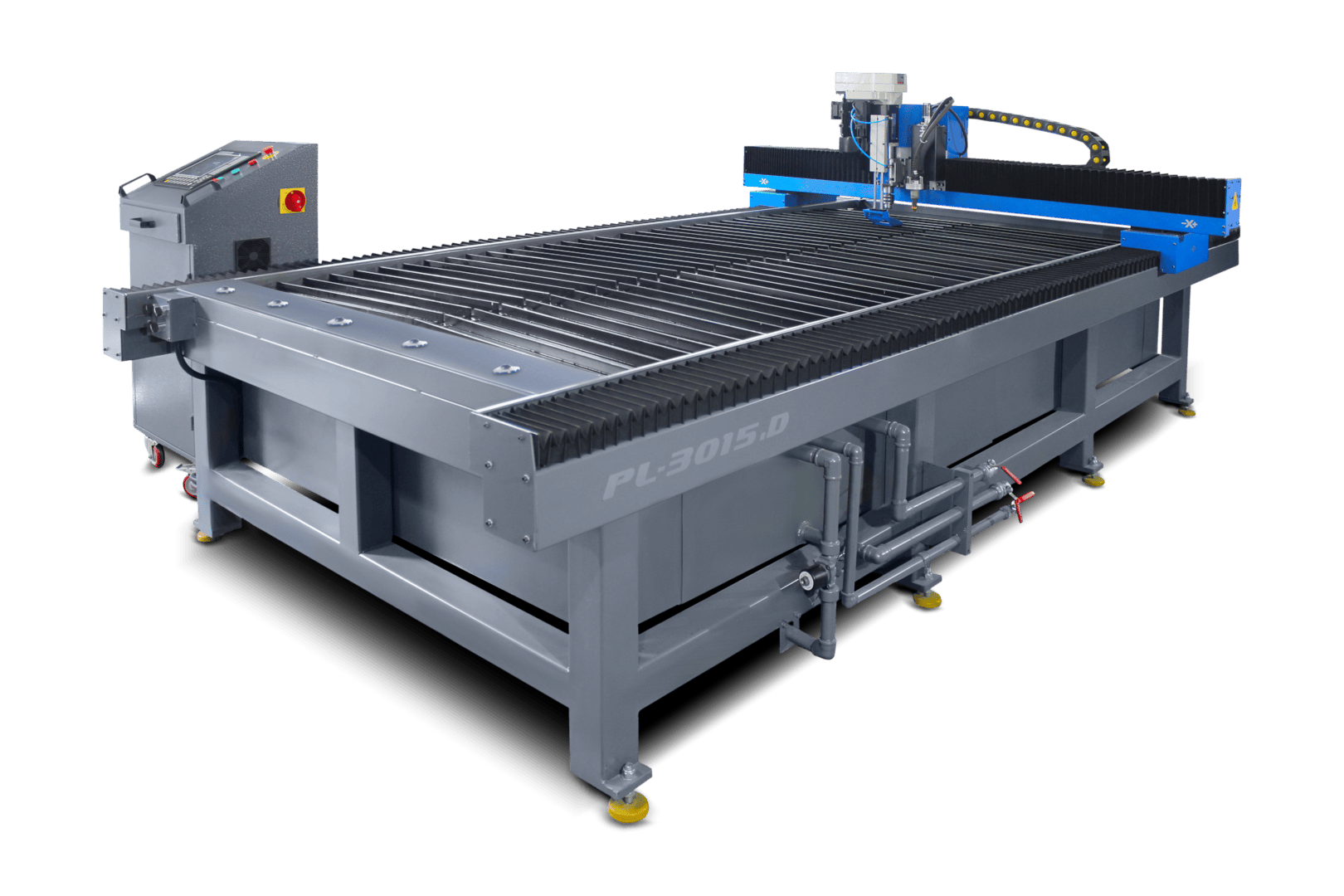

РL-3015.D plasma cutter

Highly efficient industrial equipment is developed using the latest technologies and high-quality components.

The machine is equipped with a powerful PowerMax 105 plasma source, a water-filling table with automatic level control, and a unit for coordinated hole drilling. All mechanical components are covered with corrugated protection to ensure a long service life.

The PL-3015.D plasma cutter is a versatile tool capable of processing sheet materials of various thicknesses and coordinate drilling. This versatility significantly expands the production possibilities.

-

Quality components

During the production of CNC machines, we use only high-quality brand components. They guarantee the accuracy, reliability and long-term operation of CNC routers

-

Professional production

During the existence of the company, we have established ourselves as a professional production that is actively developing and working on the modernization of equipment and the creation of new models of machines

-

Reliable spindle

Our machines use high-quality spindles from the world’s leading manufacturers with liquid and air cooling. They ensure the accuracy of material processing

-

Simple controls

CNC machines are easy to use and have an intuitive interface and control system that allows you to quickly and efficiently meet your production goals

-

Software

We use exclusively professional and licensed software that guarantees efficient machine control and minimizes the risk of malfunctions

-

Service

We provide expert advice and assistance in selecting equipment for your needs and commissioning works. We also ensure the best terms for training and CNC machine maintenance

-

Guarantee

The guarantee for all CNC machines is one year. We also provide post-warranty technical support and equipment maintenance throughout our machines’ period of operation

-

Industrial manufacturing

Manufacturing of CNC machine tools takes place at our production base using precise equipment and careful observance of all the processes and standards of machine tool construction

Information

Information

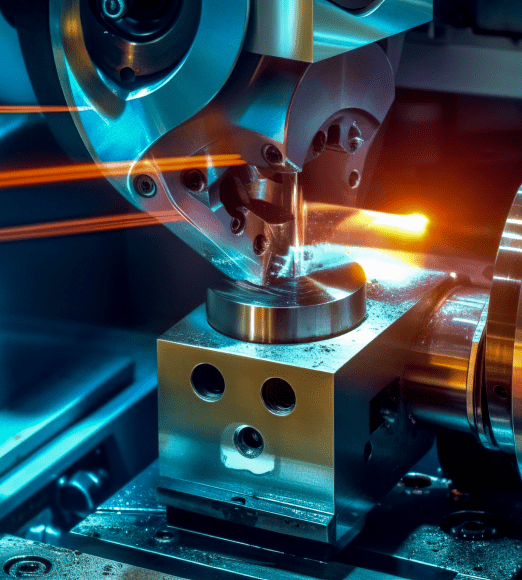

The machine is designed to cut metal sheets of various grades. Metal cutting is performed with a plasma jet. The PL-3015.D machine is a technological complex with a plasma torch mounted on a CNC coordinate table.

Advantages of the model

- High cutting precision

- Clean cuts

- Processing metals

- Processing of profiled rolling

- Perfect repeatability of finished parts

- Working with complex surface configurations

Worktable size

Y-3000, X-1500, Z-150

Materials that can be processed

- Steel

- Stainless steel

- Cast iron

- Aluminum

- Non-ferrous metals

Application areas

- Production:

- Equipment manufacturing

- Bridge construction

- Agricultural machinery manufacturing

- Electrical cabinets production

- Armored doors manufacturing

- Metal structures manufacturing

Construction

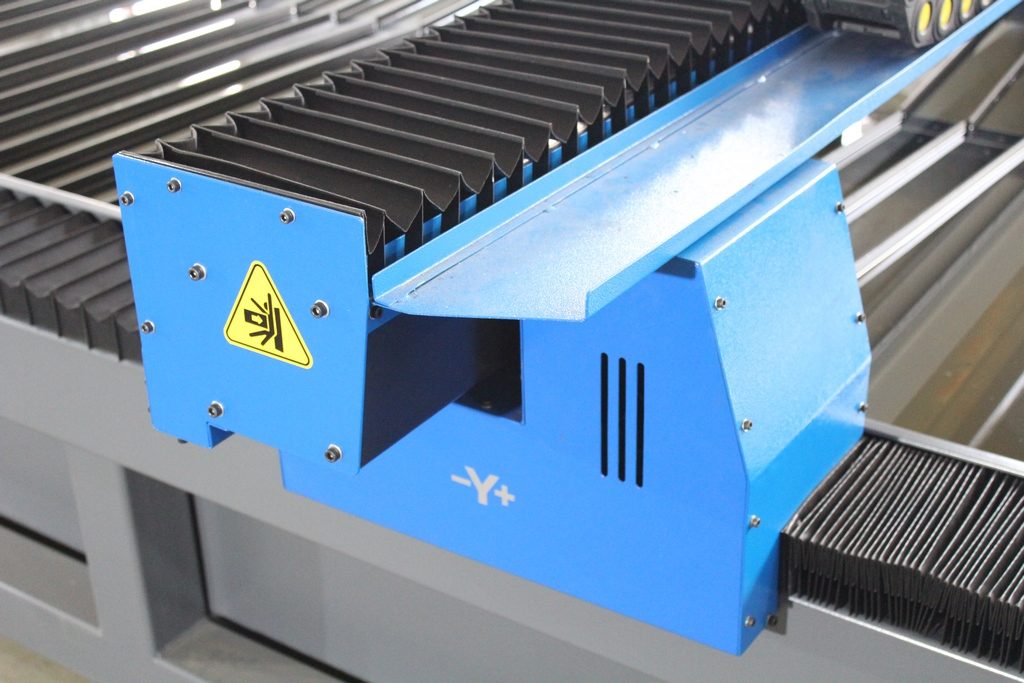

The high-quality components used in manufacturing the CNC machine PL-6020 ensure its reliability and stable performance. The machine’s base is a solid welded frame made of profiled tubes processed using a CNC portal center. The user-friendly control system ensures stability and precision in the machine’s operation.

Specifications

Machine type

Plasma cutting

Construction

Moving gantry

Table work area (Y×X)

1500×3000 mm

Axes travel (Y×X)

1500×3000 mm

Table wor

Slatted

Linear guide rails

Precision linear guideway

X, Y axes feed

Helical rack

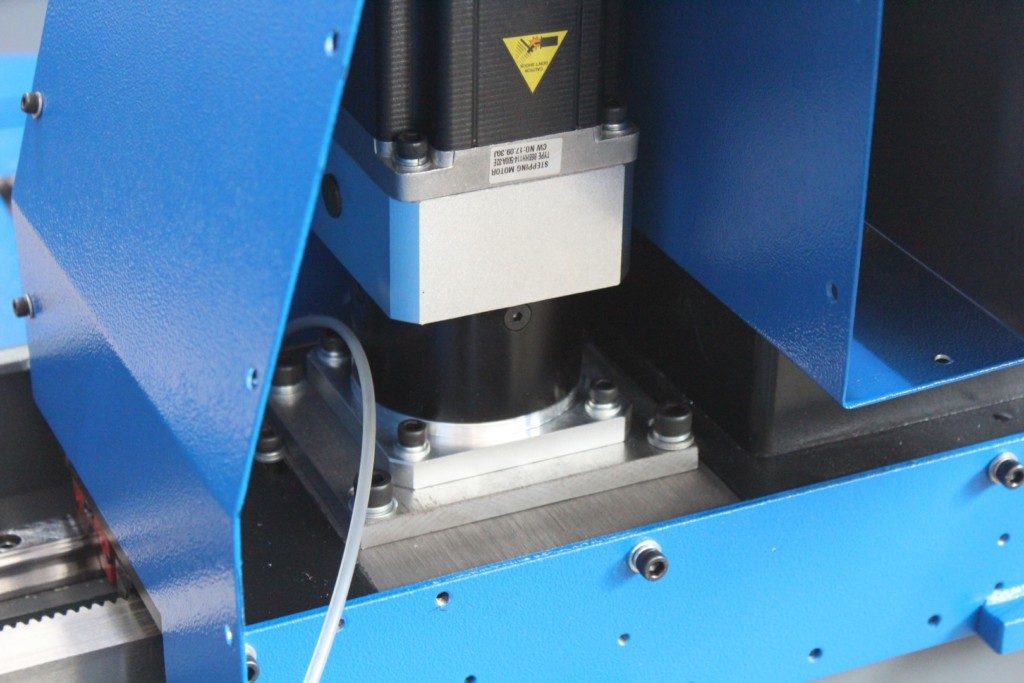

X, Y axes motors

Stepper motor

Maximum traverse speed, axes X, Y

20 m/min

Work feed rate up to

1-20 m/min

Plasma source manufacturer

Hypertherm PowerMax

Plasma source model

105A | 125A

Current adjustment

Manual

Control system

StarFire 2100.S

Software

Built-in library

Drilling unit

QD3

Drill chuck mount Ø

0,8-13 mm

Max drilling Ø

Steel – 13 mm, Aluminum – 16 mm

Max thread cutting

Steel – M16, Aluminum – M20

RPM

1300

Machine power requirements

220 W 50 Hz

Plasma source power requirements

380 W, 50 Hz

Power consumption

10-25 кW

Machine dimensions (L×W×H)

3400×2100×1300 mm

Machine weight

1500 кg

FAQ

Do you conduct machine installation and training?

Yes, we do. Upon the client’s request, our specialists perform installation work and provide training on the basics of machine operation and creating toolpaths.

Can colour metals and stainless steel be cut?

Fibre laser cutting machines allow the cutting of colour metals and stainless steel. Nitrogen is used as the auxiliary gas for such operations.

Is there post-warranty support and maintenance available?

We provide post-warranty support and service for all our machines. Mechanical and electrical parts used in our machines are always in stock.

How do you protect a CNC machine from power surges?

As the manufacturer, we also recommend installing a voltage stabilizer at the CNC machine’s input to ensure stable operation and avoid issues related to power surges.

Do you offer shipping?

Depending on the region of Ukraine, we provide equipment shipping through our transportation or other courier companies. We have also developed turnkey solutions for overseas businesses.

Get New Quote Today

The machine can be produced in various modifications and equipped with options of your choice.

We can help you choose the optimal machine for your projects. Get Pricing Info & Have Our Machine Quick Reference Guide E-Mailed To You Today!